ISJ Exclusive: (Re)Building a camera company for the AI age

James Thorpe

Share this content

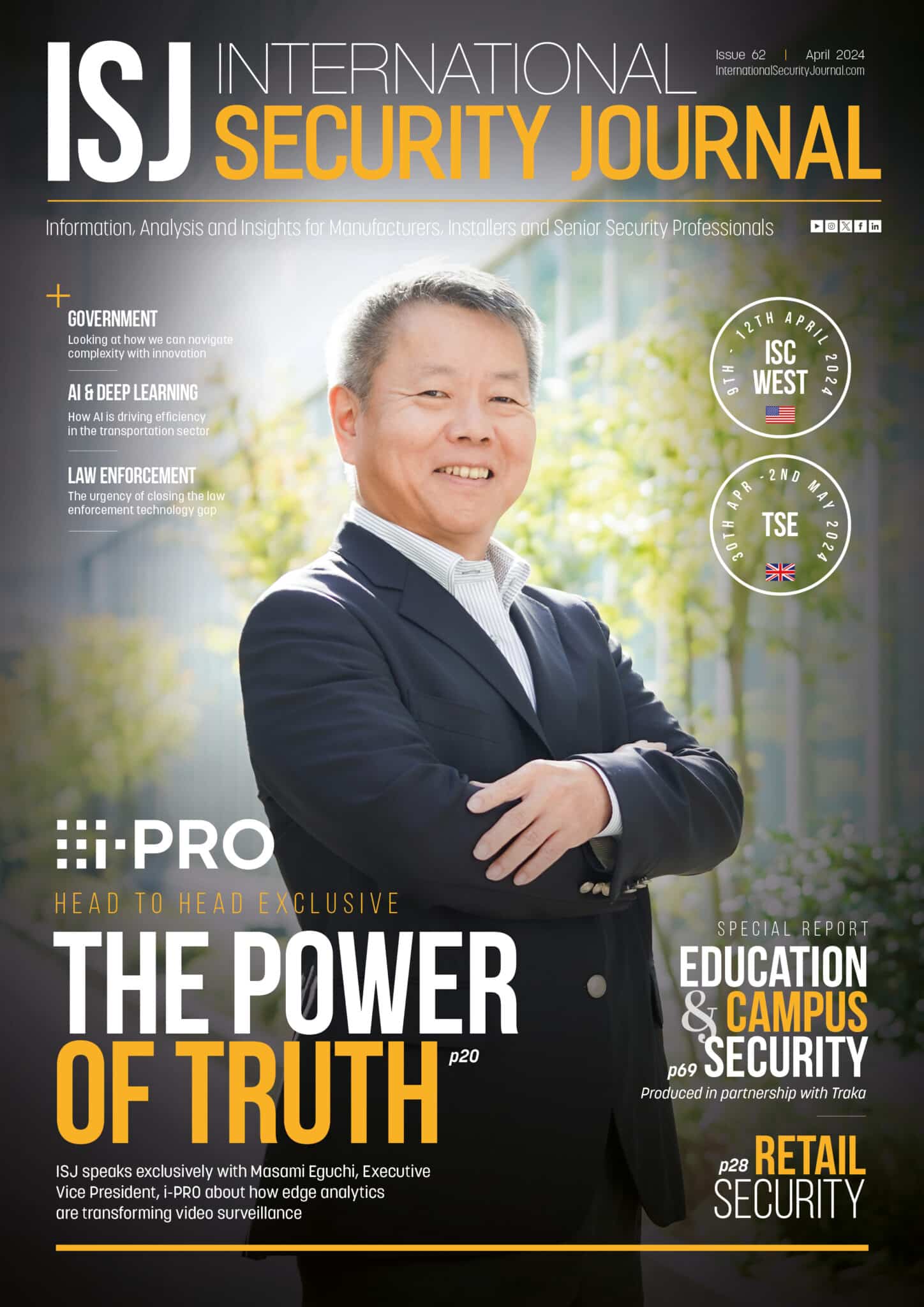

ISJ speaks exclusively with Mr. Masato Nakao, Representative Director, Chairman of the Board and CEO, i-PRO Co., Ltd.

In April 2022, Panasonic i-PRO Sensing Solutions changed its name to i-PRO, separating itself from the name of its original parent company, as it became independent. In this Head to Head Exclusive, ISJ sat down with Mr. Masato Nakao, the company’s Representative Director, Chairman of the Board and CEO, who explained that this was not simply a brand change – it represented a monumental turning point that redefined the company’s business field, reconnected relationships and reformed its organisation.

The following is a wonderfully transparent conversation with Mr. Nakao on the transformation of a company that has set itself up for an entirely new way of doing business in the video surveillance market. From made-to-order manufacturing and faster supply chains to open systems that usher in an “app economy” model for customisation, to cybersecurity built in by design, he answers questions about how this model will move the industry forward as the age of AI analytics dawns.

Mr. Nakao, can we start by talking about what the company looked like before its transformation to i-PRO? What were you looking to change?

i-PRO’s origins go back to 1957, when Matsushita Electric Industrial’s Central Research Laboratory developed a professional surveillance camera. By the 1990s, the company had experienced several mergers and had become a world leader in image sensing. But, we were slow to adapt to business and technology changes and fell behind in the global market.

Our competitors had redefined the playing field with new technologies and business models. Panasonic had opted to expand vertically, from creating hardware products to providing end-to-end solutions. The rest of the market was expanding horizontally and partnering on solutions. They created new markets without us. To recapture the global lead our predecessors had carved out, we needed to take up a new business model, reform our principles of competition and pioneer new markets. It meant changing everything, starting with our core beliefs.

I’ve read about the two concepts on which you based i-PRO’s strategy – could you tell us about “time-based competition” and “open policy”?

Open policy refers to horizontal specialisation. i-PRO is a hardware manufacturer specialising in the development of cameras, our field of expertise. When hardware alone doesn’t meet the customer’s needs, specifically in image analysis software, video management software and system integration, we share the work with our leading global partners. As part of Panasonic, we provided all four, which put us in competition with partners.

Under our open policy, we have aggressively rebuilt relationships with VMS vendors, AI analytics vendors and integrators. We focus on being the best hardware on these platforms to enable our partners to address the needs of a broad end user customer base. Our 2022 results show that our open policy has become a major driving force for i-PRO’s growth. Additionally, as i-PRO, we continue to offer this comprehensive strategy, which in the Americas is focused on and developed primarily for the education market.

The other foundational concept of our strategy, time-based competition, focuses on time as a source of competitive advantage. For example, we can minimise time that does not produce added value and cut lead time, helping reduce customers’ opportunity costs, providing a basis for premium cost and achieving profitable growth. Operational excellence and process innovation are key to executing this strategy.

Our decision to expand our new manufacturing capability in Japan in close proximity to our engineering and design teams is an example of a time-based advantage that enables us to rapidly produce a range of customised camera products while reducing delivery times.

How does i-PRO’s adoption of these concepts help organisations meet the challenges and opportunities of AI analytics?

As AI-based technologies advance, the industry will see specialised tools being created by expert developers with a focus on solving unique challenges. Analytics technology will change rapidly and it’s impractical to expect organisations to buy a new camera to access these new advancements. Open platforms give developers access to a larger market. Like today’s app-based economy for computers and smartphones, this model will continue to take shape and offer integrators and organisations the same level of customisation they’ve come to expect from consumer technology, in their professional video surveillance technology.

Consider too the manufacturing implications of customising AI solutions for each project. There is little standardisation; therefore, there is no room to achieve mass production that would engage economies of scale. For i-PRO, we see an opportunity in being able to increase the variety of our AI-compatible cameras and immediately supply even just single units.

Our ability to implement a high-mix/low-volume strategy that enables made-to-order manufacturing will allow us to standardise the production of core camera modules with a high level of customisation to meet customers’ unique requirements. By leveraging similar components across designs, we can significantly reduce manufacturing time while increasing the number of models compared to traditional manufacturing methods. We believe this unique capability, that i-PRO alone has built, will help to accelerate growth of the AI analytics market overall.

How does i-PRO’s manufacturing process differ from other manufacturers’ or from the old Panasonic/i-PRO’s way of doing things?

In traditional manufacturing, companies develop products in order of the models they expect will be in greatest demand. Design and development rules focus on developing the optimally designed product at minimal cost per model, without redundancy. As a result, it takes a long time to make each model, and the number of products that can be developed each year is limited. Production, sales and inventory planning systems also add to the lead time of delivery and make it more difficult for manufacturers to respond promptly to changes in demand.

At i-PRO, essentially, we do not develop finished products, but in 2020 switched to developing modules (general-purpose, half-finished products) for use in various types of products. Module design is actually more difficult than designing from scratch, model by model. This is because it is necessary to design in response to diverse needs while minimising redundancy and consider how to guarantee maximum compatibility between modules. For example, if you develop multiple modules with a high degree of versatility, it is possible to define all final products as a combination of them. The effectiveness of this is clear: The development cycle for one model is significantly reduced and the number of new product models that can be released each year increases greatly.

In the fast evolving digital industry, development cycle speed has greater significance than product range. By constantly incorporating the latest sensors and semiconductor chips released by suppliers into products faster than other companies, it is possible to retain the lead in product performance.

On the manufacturing front line, we mass produce these general-purpose modules to leverage the economy of scale and retain them as inventory. We await orders with half-finished products, then quickly assemble and ship in response to demand, enabling us to immediately respond even to small-volume needs much faster than our competitors. This approach also makes us less vulnerable to supply chain inconsistencies.

Has i-PRO suffered with supply chain issues?

Thankfully, no. In addition to our manufacturing approach, and because i-PRO has its own manufacturing facilities in multiple locations globally, we were able to minimise the supply chain issues that we’ve seen devastate some of our competitors who saw their bottom lines impacted even as market demand went up.

What about other external pressures that are out of i-PRO’s control, like cyber-threats? How do you minimise that aspect of the new reality for your customers?

With the disturbing rise of cyber-attacks, it’s clear that manufacturers must do more to help secure cameras and other IoT devices and educate the market on security best practices. i-PRO focuses on guiding customers around what we believe are the four foundational elements of any IoT security program: Resiliency, cyber hygiene, product security and proper configuration.

Product security, particularly the security features on the devices themselves, is where manufacturers have the biggest responsibility. Many IoT devices, especially low-end products or those made by fly-by-night companies, don’t have built-in security features. i-PRO’s products do – like encryption, authentication and support for secure network standards like 802.1x. We are also diligent about fixing any security flaws that may be reported.

We expect more European governments to follow the USA NDAA example that prevents authorities from installing non-NDAA compliant surveillance systems in sensitive sites and anticipate continued adoption of zero trust practices that validate every transaction between devices and people. We have adopted cybersecurity as a pillar of corporate responsibility at i-PRO to help our customers safeguard business continuity. This isn’t a new concept – security by design is a part of i-PRO’s DNA.

What do you see as i-PRO’s role in the coming wave of AI analytics?

Allow me to respond with a story from history. During the gold rush of 1849, prospectors flocked to California in the hope of striking it rich. Who had the most success? Was it James Marshall, whose discovery started it all? Or one of the thousands of people who converged on the scene? No. It was Levi Strauss. He didn’t develop ground-breaking technology or lend a hand in prospecting. He made and supplied high quality jeans made of a thick, strong canvas. Because he took out a patent that lasted for 20 years, he alone was able to deliver his product to a market specifically in need of it.

If we compare vendors who offer analytics and system integration using AI with the 49ers, i-PRO aims to be like Levi Strauss. We will not compete in the search for gold. Instead, we will supply innovative, reliable AI-compatible cameras in a range of models promptly upon order.

In the same way that many ambitious people traveled west hoping to find fortune, there are now many players, big and small, clamouring to provide AI-based solutions around the world. But there are few camera manufacturers with established technologies suited to the unique needs of the AI sphere. That’s what we have built and what we alone are delivering.

This article was originally published in the March 2023 edition of International Security Journal. To read your FREE digital edition, click here.