Dahua AI technology helps create the “smartest” dam in the world

James Thorpe

Share this content

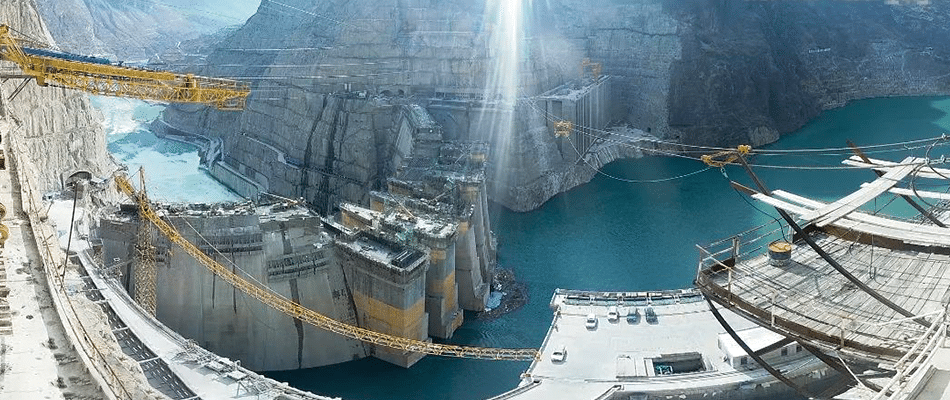

Dubbed as the ‘smartest’ hydropower station in the world, Wudongde Hydropower Station is located in the upper stretch of the Yangtze River in the Sichuan and Yunnan provinces of China. It is the country’s 4th largest hydropower station and 7th largest in the world, with an estimated annual output of 38.91 billion kWh. The Wudongde Dam adopts the world’s thinnest 300-metre double-curved arch dam design. It must be able to sustain the water storage capacity of a millionth-level super large hydropower station, which poses a great challenge in terms of the crack resistance of the dam.

Digital construction of a crack-free dam

In order to achieve a “crack-free dam”, the entire dam used low-heat cement (the first in the world) that has extremely strict requirements on concrete processing technology and temperature control. In addition, the station is built with a series of digital and advanced technologies, including real-time temperature monitoring, AI, IoT, AR, etc.

Dahua’s AI-based intelligent video analysis algorithm realises the digitalisation of the whole process of concrete production, transportation, pouring and maintenance. It provides visual control of the concrete tamping process, reduces demolition and modification of the structure and saves construction time.

Moreover, thermal imaging + blackbody technology was utilised to conduct quick and accurate contactless temperature measurements during the whole process: from the mixing plant to the storage surface of the dam. It conducts real-time sensing of the concrete’s temperature and provides early warning if the threshold is reached, reducing the randomness and subjectivity of manual monitoring, ensuring that the concrete’s temperature is controlled and improving the quality in order to prevent any possible cracks.

Also, the solution adopted video sensing and Internet of Things (IoT) technology to get real-time data of the dam’s current condition. It conducts intelligent analysis using the collected data, which can significantly help decision makers to adjust on-site technical indicators and monitor the dam’s temperature in a timely manner. The entire solution promotes high quality standards, long-term safety and reliable operation of the dam.

AI identification and early warning ensure construction safety

Construction safety is of paramount importance in building a dam on a nearly 90 degrees of high and steep rock wall. Utilising visual analysis technology based on deep learning, the solution can dynamically monitor the operators on the high and steep slope of the dam abutment and storage surface. With the help of AI, it provides early warnings by identifying unsafe worker behaviours in the facility (e.g. not wearing safety helmets and entering restricted areas), allowing managers to remotely respond in time. The system also offers a people counting feature on the site, so as to ensure an orderly and safe access for every worker and to provide data support for safety management.

AR holographic map shows real-time view of the scene

In this project, Dahua fully utilised its professional video capabilities and integrated real scenes with virtual 3D panorama. The actual scene of the dam under construction and the virtual scene of the completed dam are displayed simultaneously to monitor the development of the dam’s construction. This integration together with a 3D display of multi-source visual data present every moment of the building process of the hydropower station. At the same time, through AR holographic map, the whole visual and dynamic management of the dam’s construction can be realised, which helps visualise the progress of the project and improve its management strategies.

More refined management with smart platform

The Dahua solution breaks traditional infrastructure management strategy that is commonly used in the industry. Through the development of an intelligent monitoring platform based on machine vision, the system deployed in the dam offers various integrated functions including temperature control, output quality identification, site safety control, holographic sensing, etc. It is also connected with the intelligent manufacturing system of the customer, which contributes to the visualisation, standardisation, digitalisation and intelligent control of the entire Wudongde Dam.